Your cart is currently empty!

The 5 Best Glues For Basing Wargaming Miniatures

Wargamers, like you, need the best glues to make good-looking, durable wargaming bases that don’t detract from gameplay.

Contents

Terrain Wizard’s Choice For The Best Glue

PVA, sometimes called white glue, is the most versatile glue for basing. Whether in its regular formulation, decoupage medium, or tacky glue, it is a must-have for basing.

Some Questions Answered

What Is Glue

An adhesive, often called glue, is a substance that binds two materials together.

How Do Things Stick Together

There are five commonly recognized ways that adhesion works:

- Chemical adhesion – molecules at the material’s surface chemically bond with molecules in the adhesive.

- Mechanical adhesion – the adhesive flows into the pores on the material’s surface, interlocking them.

- Dispersive adhesion – molecules at the surface of the adhesive attract and hold the molecules of the material through van der Waals forces.

- Diffusion adhesion – the adhesive penetrates the material at the molecular level and entangles its molecules with the material’s molecules.

- Electrostatic adhesion – the boundary between the adhesive and the material acts like a capacitor creating an attractive electrostatic force.

Things To Think About

The Five Best Glues For Basing

1 Polyvinyl Acetate – PVA

As a water-based dispersion, PVA is a widely available adhesive for porous materials like wood, paper, and cloth. When wet, it is a white liquid but dries to a clear, colorless finish.

It comes in several formulations, which are very handy for basing.

Craft or White Glue

White glue, craft glue, wood glue, carpenter’s glue – whatever you call it, PVA glue is the workhorse of terrain building. It is just as crucial for basing a single figure as building an entire wargaming table.

Because it is water-soluble, you can thin it with water to make a sealer. It cleans up easily with soap and water.

Additionally, PVA glue remains flexible after it has dried. Thus it wears better than other glues.

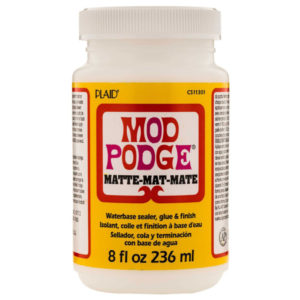

Mod Podge

Mod Podge is a decoupage medium. It is a latex emulsion mixed with a plasticizer. So it is a glue, sealer, and finish.

Jan Wetstone developed the product in 1967; because she wanted a ‘modern decoupage’ medium, Mod Podge. Patented in 1971, Mod Podge initially used a 55% PVA emulsion mixed with the plasticizer, dibutyl phthalate.

Today Mod Podge comes in many formulations. It bonds irregularly shaped elements and fills gaps in clump foliage. It also creates water surface effects like ripples, waves, and surf. Also, it is a matte and gloss sealer.

Tacky Glue

Aleene Jackson developed the formula for floral arrangements. At the time, no thick high tack quick setting glues were available. Today, Aleene’s Orginal Tacky Glue is the first and still the most widely used tacky glue formulation.

It bonds irregularly shaped pieces. With its fast-grabbing tack, it makes quick work of complex bases.

2 Cyanoacrylate – CA

Harry Coover worked for B. F. Goodrich Company. He headed a team of scientists who discovered Cyanoacrylates in 1942. Later, he went to work for Eastman Kodak, which released the first commercially available CA glue, Eastman #910, in 1958. Today it is widely available and goes by several common names – CA, Super Glue, Krazy Glue.

CA glues cure by polymerizing in the presence of water. Thus CA glues take longer to set in low humidity conditions like desert climates and the winter. You can improve the cure time by using a kicker.

CA glues have a reputation for making fast, strong bonds to practically anything – especially between fingers. It needs a clean surface free of oil and dirt to bond.

CA forms strong bonds with metal, ceramic, leather, rubber, vinyl, and some plastics.

But it bonds poorly with several plastics:

- polyoxymethylene(POM), like Delrin

- High Density Poly Ethylene (HDPE)

- polypropylene (PP)

- Polytetrafluoroethylene (PTFE), like Teflon.

You can improve your experience with CA in three ways:

- Use a CA accelerator

CA accelerators are mixtures that increase the cure speed of CA. Because they speed things along they are often called kickers.

The active ingredient is amine. Adding amine before bonding and curing takes place makes things go faster. The amine is mixed with solvents, usually acetone, heptane, or ethyl alcohol, that act like a carrier.

The carrier spreads the amine evenly and then evaporates rapidly without leaving any residue.

They are especially helpful in low-humidity environments.

Kickers are easy to use. You can get them in pump spray bottles, aerosol cans, felt tip applicator pens, or bulk containers. You can apply a kicker to the surfaces you want to glue before applying the CA glue. Usually, you apply the CA to the surfaces, make sure the alignment is right, then apply the kicker.

- Use a CA primer

CA primers work like paint primers. They stick to a surface that CA won’t bond to, so the CA can stick to the primer.

FOR BONDING WITH POLYOLEFINS, PTFE, POLYETHYLENE, POLYPROPYLENE, AND DIFFICULT PLASTICS

These compounds are generally employed in assembly applications between difficult-to-bond materials. Examples include polyolefins and other low surface energy plastics such as (EPT) ethylene propylene terpolymer rubber, polyethylene (PE), and polypropylene (PP). Other challenging materials are silicone rubber, soft PVCs and glass.

Primers should be applied to the substrate before the application of the adhesive to the bonding surface. When using primers in cyanoacrylate application operations, some guidelines include:

- Use the appropriate primer for the bonding material (e.g., polyolefin primers for polyolefin plastics)

- Allow the solvent to evaporate off the bonding material before adding the adhesive

- Change the CA viscosity

- Thin CA has the viscosity of water, about 5cps, so it does a good job wicking into tight spaces.

- Medium CA has the thickness of SAE 10 Motor Oil, 80-120cps, so it is an excellent general-purpose adhesive.

- Gap-filling CA has a viscosity of honey, 1150-1500cps.

3 Plastic Cement

Plastic cement is a volatile liquid that joins plastic elements together through a process known as solvent welding.

The process melts the plastic, so the two pieces permanently fuse when the cement cures.

Use It For Figures And Bases

You may already be using plastic cement to assemble miniatures. You could use the same glue to base your figure.

Suppose you are creating custom elements for a base. You might use Polystyrene(PS) building materials like bits of sprue, Plasticard, and custom pieces like tiny skulls. In that case, you are using it as a basing glue.

Choose The Right Formulation

Plastic cement comes in several formulations. There are several different chemicals used as welding agents. Check the product label for proper use.

You can also get different viscosities. Very thick formulations help fill gaps and join large pieces because they don’t run. Very thin formulations wick between tight-fitting pieces.

Plus, plastic cement comes in several different packages. The simple tube with a cap is perhaps the most common package. But bottles with built-in applicator brushes are also available. There are also glue pens with built-in applicators that minimize the mess. Specialty needle tip applicators can ease working with small or cramped joints.

Read The Label

Be sure to use plastic cement in a well-ventilated area. Read and understand the product label to ensure safe usage and handling. You may develop a sensitivity to the volatile components.

Plastic cement is an excellent way to bond plastic. Unfortunately, it does not weld other materials like resin, metal, or paper products. So it has limited value for basing.

4 Two-Part Epoxy

Two-part epoxies get their name from their two ingredients – the resin and the hardener. You must mix the resin and the hardener to trigger curing.

When you combine the two, you start a chemical reaction. The reaction cross-links molecules to produce a polymer. The process makes heat, so it is called an exothermic reaction.

The reaction takes a few minutes. When complete, the bond is essentially a rigid piece of molded plastic.

Many Formulations

5 Hot Glue

Final Thoughts

PVA is the foundation glue for all basing. It adheres to the broadest range of materials. Also, it works well as a sealer.

But it doesn’t reliably bond to plastics and metals.

So you may want to add CA to your toolbox. It works well to bond elements to your base. Ensure it is thick enough to stay put and fill gaps while setting.

Then you can add the final embellishments and seal it with PVA.